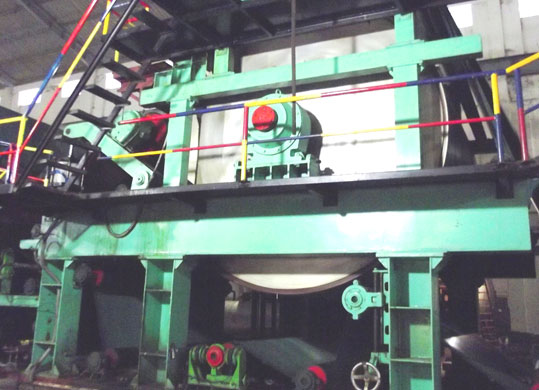

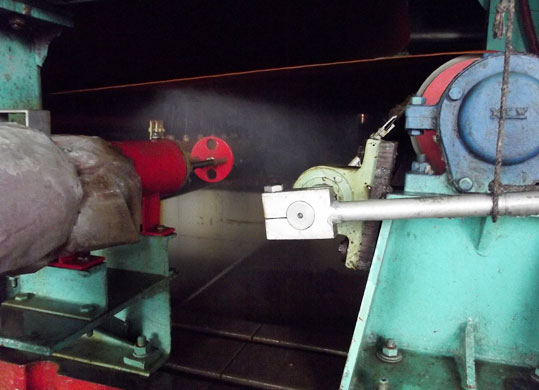

Types of Machine Manufactured by us:

- Fourdrinier Machine.

- Mould / Former Machine.

- Fourdrinier — Mould Combined Machine.

- Twin Wire Machine / Multi Layer Fourdrinier Machine.

- Yankee Machine.

- Sundry Machine.

Types of Machine Manufactured by us:

Themes by themesfreedownloader.com