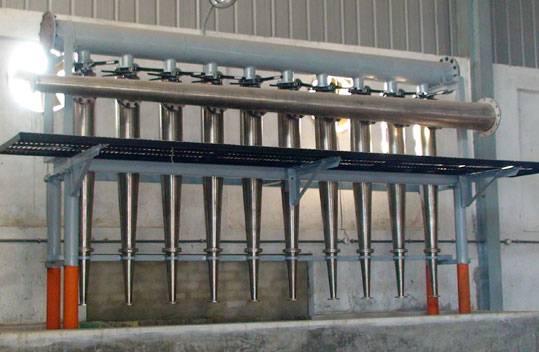

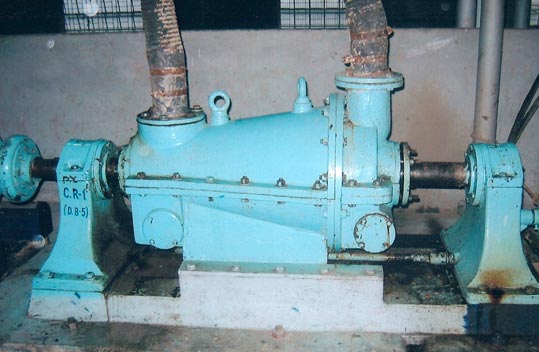

ROTARY SPHERICAL GLOBE DIGESTER

- Used for batch cooking of wood or agricultural waste to produce fibers for paper making.

- We manufacture Rotary Spherical Globe Digester in various sizes – 12 ft. to 16 ft.

- Tested Prime quality IS:2062 plates are used for manufacturing Digester. The Unique feature of our Digester is that we are the only manufacturer who for additional strength do riveting of plates by providing an additional re-enforcement plate on every joint in addition to the weld joint.

- Digesters are hydrauiically tested to a pressure of 175 psi.

- We have manufactured more than 100 Digesters till date.

- Provided with Conveyor for Feeding of Raw material.